Sodium Alginate-Lignin Fibers: A Sustainable Nylon Alternative

Abstract

The textile industry heavily relies on synthetic materials like nylon, which are durable but contribute to environmental pollution due to their petroleum-based composition and non-biodegradability. With the rise of fast fashion, clothing waste and microplastic pollution have increased significantly. This research explores biodegradable alternatives to nylon, specifically investigating sodium alginate polymerized with lignin to develop a sustainable textile material. The study aims to determine whether this biodegradable material can match key properties of nylon, such as linear density and tensile strength.

To achieve this, nylon was first synthesized as a baseline for comparison. Then, sodium alginate and lignin were polymerized in varying ratios to test their mechanical properties (1:1, 2:1, and 9:1). The materials underwent tensile strength, elasticity, and linear density testing. An analysis of variance (ANOVA) was performed to identify the most promising composition that closely mimics nylon’s properties. Among the tested formulations, the 1:1 sodium alginate-lignin ratio demonstrated the highest breaking force and was statitically comparable to twisted nylon in tensile strength.

Preliminary research indicates that sodium alginate and lignin have potential as biopolymer alternatives, with sodium alginate offering flexibility and lignin contributing to strength. However, optimizing their combinations is crucial to achieving the necessary strength and durability for practical textile applications. This research provides valuable insights into developing sustainable fashion alternatives, reducing dependency on petroleum-based fibers, and promoting eco-friendly textile production. If successful, the findings could encourage innovation in biodegradable fabrics, addressing the growing environmental concerns associated with synthetic textiles.

Literature Review

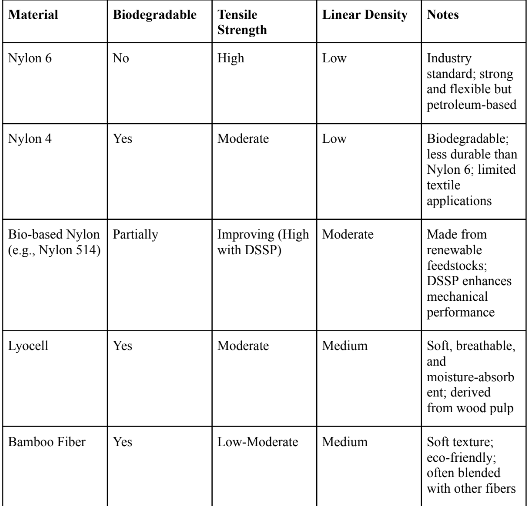

As environmental sustainability became a growing concern across industries, especially in fashion and textiles, the demand for alternatives to synthetic materials increased. Nylon, while valued for its strength, flexibility, and affordability, is derived from petroleum and does not biodegrade, contributing to long-term environmental pollution. The following table summarizes the mechanical and sustainability characteristics of the key synthetic and biodegradable alternatives discussed for quick reference.

In response, researchers began investigating biodegradable materials that could replicate synthetic materials’ performance while reducing environmental impact. Plant-based polymers and modified bio-nylons have emerged as potential candidates, but many still fall short in key areas such as tensile strength and linear density.

Through looking at the composition of Nylon, it was found that Nylon 6 is used for textile production and is non-biodegradable, and Nylon 4 is often used for temporary items due to its lower durability, but it is biodegradable. Fukuda and Sasanuma (2018) compared Nylon 4 and Nylon 6, showing that Nylon 4 is biodegradable and still has similar mechanical properties to Nylon 6, which is widely used. They also highlighted that Nylon 4 is made from biobased sources, which reduces reliance on fossil fuels. Similarly, Cerbule et al. (2022) studied biodegradable fishing nets as a replacement for nylon nets. While biodegradable nets are better for the environment, they are not as strong or effective as nylon nets, which shows the need for improvements. Using this study, it was concluded that Nylon 4 would not be a feasible alternative to Nylon 6 in terms of textile production due to its low tensile strength and durability.

Grineviciute et al. (2012) tested biodegradable fabrics like lyocell and bamboo, finding that they are often softer and more comfortable than cotton, which makes them ideal for clothing. Patterson et al. (2024) created a polyester that breaks down faster when exposed to light, offering an example of how materials can be made to degrade more easily. Research on bio-based nylons, such as Nylon 514 (Li et al., 2024) and Nylon 52 (Li et al., 2023), focuses on improving their durability and stability. Solid-state polymerization (DSSP) has been especially effective in strengthening bio-nylons and making them more practical for use.

McKay et al. (2024) reviewed chemical treatments that improve natural fibers, making them stronger and more resistant to moisture. Huang et al. (2019) showed how adjusting nylon’s chemical composition can change its properties, which could also work for improving biodegradable materials.

From this research, it’s clear that biodegradable materials have a lot of potential, but they still lack some of the strength and stretchiness that nylon has. Using treatments and new methods could help improve their properties. This research will test biodegradable materials to see if they can act as a realistic replacement for nylon in textiles. Specifically, it is going to be tested whether sodium alginate mixed with lignin fiber could be compared to the monomer chains of nylon. Because there was no access to industrial-level spinning equipment to produce true textile-grade fibers, this study tested the tensile strength and linear density of monomer strands instead. This limitation may affect the direct applicability of results to real-world textile manufacturing, as fiber uniformity, elasticity, and processing behavior at scale could differ significantly. Future research could benefit from collaboration with textile engineering facilities equipped with fiber extrusion or wet spinning capabilities to more accurately evaluate performance in practical applications.

Research Question and Engineering Goal

To explore the viability of biodegradable alternatives to synthetic fibers, this study posed the following research question: Can polymerizing sodium alginate with lignin and testing varying percentages of each in solutions result in a material that behaves comparably to nylon 6 regarding strength and linear density? The purpose of the investigation was to gather sufficient data to determine whether such a biodegradable material could serve as a sustainable replacement for nylon.

The primary engineering goal of this research is to develop a sustainable textile material that matches nylon’s key properties—durability and linear density. To achieve this objective, a series of experiments was conducted to evaluate the mechanical properties of sodium alginate-lignin composites. Through this testing process, the study aimed to produce a material capable of withstanding everyday wear and reducing dependence on petroleum-based materials. If successful, the findings were intended to support the advancement of sustainable fashion by offering a practical and environmentally responsible alternative to nylon.

Methods and Materials

Due to the chemical processes involved in this research, several safety precautions were implemented to minimize risks. Appropriate personal protective equipment, including gloves and splash-resistant goggles, was worn at all times. The nylon polymerization was conducted under a fume hood to prevent exposure to harmful fumes. All chemicals were handled and disposed of in accordance with safety regulations, and testing equipment was operated with care to avoid injury. Emergency safety equipment, such as an eyewash station, was kept accessible throughout the experiment. These protocols helped mitigate potential hazards associated with the experimental procedures.

To evaluate the viability of sodium alginate and lignin as a sustainable alternative to nylon, the research followed a structured process involving polymerization, mechanical testing, and comparative analysis. This began with synthesizing nylon as a performance baseline, followed by the polymerization of sodium alginate and lignin mixtures. Both types of materials were then subjected to mechanical testing to assess tensile strength and linear density.

The first stage of this experiment involved the polymerization of nylon. A beaker was prepared with 50 mL of 1,6-hexamethylenediamine, which forms the foundation for the nylon synthesis. Carefully, 50 mL of Adipoyl Chloride was poured along the side of the beaker to create an interface between the two solutions. As the nylon polymer forms at this interface, forceps were used to carefully extract and wind the polymerized strands around a glass stirring rod. To enhance its flexibility, the nylon was rinsed in water and then soaked in a 5% glycerin solution for several hours. After this soaking process, the nylon was divided into two types of strands—single and twisted—to ensure that different configurations are tested for mechanical properties. These strands were then stretched and left to dry under tension to maintain structural integrity.

Additionally, before polymerizing sodium alginate with lignin, 3%, 4%, 5%, and 6% w/v solutions of sodium alginate in distilled water were prepared to determine the optimal concentration for strand strength and processability. For each trial, 6 g of sodium alginate powder was combined with 10 g of glycerin and 5 g of sunflower oil in a 250 mL beaker to form a thick paste. Using a magnetic stirrer, 200 mL of water was gradually added to the mixture and stirred for 10–15 minutes until uniform. Each solution was allowed to rest overnight to release air bubbles and ensure consistency.

The prepared solution was then loaded into a 60 mL plastic syringe and extruded into a 10% calcium chloride bath (prepared by dissolving 30 g of CaCl₂ in 300 mL of water) to initiate ionic crosslinking. Each strand remained in the bath for 2–3 minutes before being removed and rinsed with distilled water. The strands were stretched with slight tension around a glass jar and dried at room temperature for 5–7 days. A light mist of calcium chloride was applied twice daily during the first 24 hours to prevent brittleness and cracking during the curing phase.

After determining that the 4% alginate solution produced the most consistent and strong strands, it was used as the base for lignin blends. For the 1:1 sodium alginate:lignin ratio, a 3% alginate solution was used instead to reduce viscosity and ease extrusion. Lignin was added to the pre-polymerized gel in quantities of 3 g, 1.5 g, and 0.33 g for the 1:1, 2:1, and 90:10 ratios, respectively, keeping total polymer volume at approximately 50 mL per trial. For each ratio, 5 strands were prepared (n = 5) to ensure consistency in statistical comparison. Once the strands were dried, Tensile strength was measured using a Vernier Dual-Range Force Sensor (±50 N range, 0.01 N resolution) equipped with a metal hook attachment. Each strand was looped securely around the hook, with the opposite end held taut by a fixed clamp. The strand was then pulled steadily by hand until it broke, and the maximum force recorded was used as the breaking strength. The sensor was calibrated before each session using standard weights and zeroed before every trial to ensure accuracy

Linear density was calculated by measuring the mass of each fully dried strand using a precision digital scale and dividing by its measured length in centimeters using a metal ruler.

All experiments were conducted in the same classroom setting, under consistent indoor conditions to minimize variability across trials. For each alginate-lignin ratio and nylon type, five strands (n = 5) were tested to ensure replicability and allow for statistical comparison.

With both nylon and sodium alginate-lignin samples prepared, the final phase of the experiment was material testing. To establish a performance baseline, nylon strands were tested for tensile strength and linear density. The tensile strength test determined the force required to break each strand configuration using a dual-range force sensor on a single strand of each sample (a single and twisted strand were tested for nylon). Linear density measurements assessed the mass per unit length of the strands, ensuring consistency in material comparison. Once these baseline results were obtained, the same tests were conducted on the sodium alginate-lignin samples.

Finally, an ANOVA test was used on the data collected from the tensile strength and linear density variations between the polymerized strands of nylon and the sodium alginate combined with various percentages of lignin to see if there is a solution, if any, with a certain percentage of sodium alginate and lignin that is comparable to the baseline data collected on the nylon monomer chain. The results of this analysis were used to evaluate the plausibility of sodium alginate-lignin composites as viable materials for sustainable textile applications.

Preliminary Results

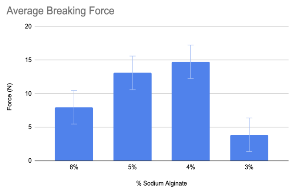

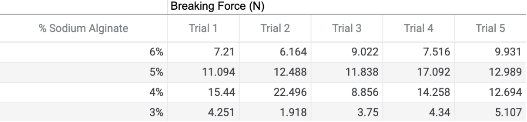

To determine the optimal concentration of sodium alginate for polymerization, initial tests were conducted using 3%, 4%, 5%, and 6% w/v sodium alginate solutions. The strands produced were assessed for tensile strength and linear density.

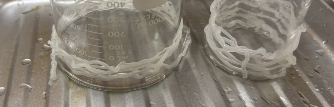

Figure 1 presents polymerized strands from 4% and 5% solutions. As shown in Figure 2, increasing the concentration resulted in thicker, denser strands. However, the 6% solution became too viscous, making it difficult to extrude evenly.

Figure 1.

4% w/v Sodium Alginate and 5% w/v Sodium Alginate solution post polymerization [all photos taken by researcher].

Figure 2.

3% w/v Sodium Alginate (top), 4% w/v Sodium Alginate, 5% Sodium Alginate, 6% w/v Sodium Alginate (bottom).

Mechanical testing data were compiled in Table 1, which summarizes the average breaking force across five trials per concentration. This data is visualized in Figure 3, where 4% sodium alginate showed a balance of high strength and manageable texture. Table 2 shows the linear density values for the same set of samples, with higher concentrations corresponding to greater material density.

Figure 3.

Preliminary data on the average breaking force of varying sodium alginate levels within the dried strings of polymerized solution.

Table 1.

Preliminary data for five trials of breaking force for varying sodium alginate levels within the dried strings of polymerized solution.

Table 2.

Preliminary data for average linear density (g/cm) for varying sodium alginate levels within the dried strings of polymerized solution.

These results led to the selection of 4% sodium alginate as the optimal base for lignin polymerization, as it demonstrated the best balance of tensile strength and manageable texture (see Table 1 and Figure 3). However, for mixtures requiring higher lignin content (such as the 1:1 ratio), 3% sodium alginate was used instead due to the increased viscosity of lignin-heavy solutions. Lowering the alginate concentration helped facilitate smoother extrusion and strand formation, which would have been difficult with the thicker 4% solution.

Results

After identifying 4% sodium alginate as the optimal base for polymerization (3% was used for the 1:1 ratio due to it being easier to extrude than 4%), three different sodium alginate to lignin rations were tested: 90:10, 2:1, and 1:1. The resulting polymer strands were analyzed for tensile strength and linear density and were compared to both single and twisted nylon strands.

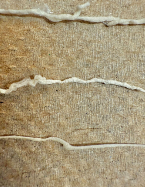

Figure 4 presents the polymerized strands for each lignin ratio. As lignin content increased, strands became visually more irregular and fibrous. The 90:10 mixture showed a relatively smooth surface, while the 1:1 blend was pretty coarse and brittle. These physical differences likely stemmed from lignin’s limited solubility and its tendency to aggregate in aqueous mixtures.

Figure 4.

Polymerized strands of Sodium Alginate (4% w/v solution) mixed with various amounts of lignin. 2:1 Sodium Alginate to lignin ratio (Top), 1:1 Sodium Alginate to lignin ratio (middle), 90:10 Sodium Alginate to lignin ratio (bottom).

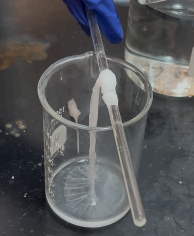

Figure 5 documents the nylon polymerization process, showing strand formation at the interface of hexamethlyenediamine and adipoyl chloride. The resulting nylon strand, displaying in Figure 6, was thinner and initially brittle, requiring twisting to more accurately reflecting textile-grade material during testing.

Figure 5.

Nylon polymerization process picture of pulling the polymerized strand from the interface of Hexanediamine and Adipoyl Chloride.

Figure 6.

Polymerized strand of nylon.

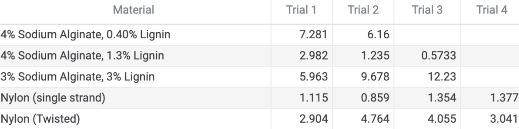

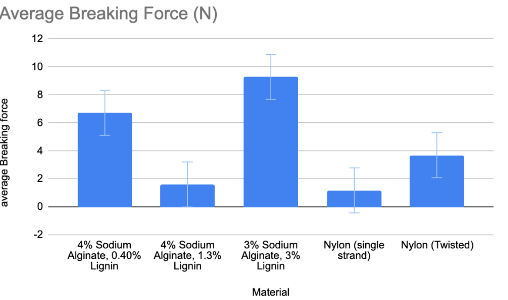

The tensile strength of each sample was measured across multiple trials. Results are compiled in Table 1, which lists the raw breaking force (in Newtons) for each configuration. Figure 7 illustrates the average breaking force per strand type, with error bars that represent the standard deviation, reflecting variation between individual trials.

Data Tables:

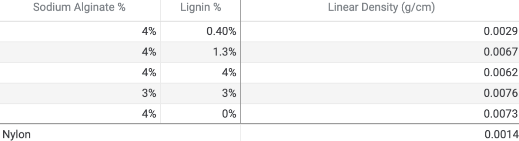

Table 3.

Average breaking force (N) of various ratios of sodium alginate to lignin, a single strand of nylon, and twisted nylon strands.

Table 4.

Linear density (g/cm) of various ratios of sodium alginate to lignin and linear density of nylon.

Figure 7.

Graph of average breaking force (N) of various ratios of sodium alginate to lignin, as well as the average breaking force of a single strand of nylon and twisted strands of nylon, including error bars to show the range of possible means.

Figure 7’s error bars illustrate the greater variability in breaking force for the alginate-lignin samples. This variance likely resulted from inconsistent lignin dispersion, uneven extrusion, and environmental drying conditions. Nylon, produced via a more controlled polymerization interface, still showed deviation in the results due to some strands being thicker than others when pulled from the interface.

The strongest biopolymer stand was the 3% sodium alginate + 3% lignin sample (1:1 ratio), suggesting promising mechanical comparability; the strands had an average breaking force of 9.290 N and a linear density of 0.0073 g/cm. Single nylon strands performed significantly worse then twisted nylon stands with an average breaking force of 1.176 N compared to 3.691 N, affirming that twisted stands are better comparison benchmark.

A two-sample t-test was performed to compare the 1:1 biopolymer sample (n = 5) with the twisted nylon strands (n = 5). The resulting p-value of 0.380674 indicated that the difference in mean breaking force was not statistically significant at the α = 0.05 level. However, the small sample sizes and relatively high standard deviations (±1.12 N for the biopolymer and ±0.72 N for the twisted nylon) limited the statistical power of the test. Future studies should include larger sample sizes and report effect sizes or 95% confidence intervals to better assess the magnitude of the observed differences. However, this does not confirm equivalence; rather, it reflects that the sample data did not provide enough evidence to reject the null hypothesis at a standard α = 0.05 level. The associated 95% confidence interval for the mean difference would likely include zero, further supporting this inconclusive finding.

Observation and Analysis

Lignin ratios enhanced tensile strength but introduced brittleness and made extrusion more difficult.

Higher lignin concentrations produced rougher and strand textures and contributed to visual and structural inconsistencies.

Manual extrusion caused irregular diameters and occasional air pockets, impacting tensile and linear density performance.

One of the alginate-lignin or nylon blends demonstrated elastic recovery comparable to that of commercial textile fibers—a critical limitation given that elasticity is essential for wearability, comfort, and fabric resilience. The brittle behavior observed in both material types suggests that current formulations lack the stretch and recovery properties required for real-world applications. To address this, future research should explore blending alginate-lignin composites with more flexible biopolymers or investigate post-processing techniques like mechanical drawing, thermal annealing, or plasticizer optimization to enhance elasticity without sacrificing strength.

Twisted nylon strands remained the benchmark for strength throughout testing.

Further Recommendations:

Increase the number of replicates to reduce variance and increase statistical power.

Use a syringe pump or automated extrusion system to ensure uniform strand formation and reduce inconsistencies caused by manual extrusion. To further enhance reproducibility and strand quality, future studies should incorporate digital image analysis software (e.g., ImageJ) or laser micrometers to objectively measure and quantify strand diameter and uniformity across samples.

Explore post-processing techniques such as mechanical drawing or heat treatment to enhance elasticity.

Investigate additional plasticizers or flexible biopolymer additives to reduce brittleness.

Conduct further testing on real-world textile properties like moisture handling, wash durability, and wear resistance.

Discussion and Conclusion

The results of this research showed that sodium alginate-lignin polymer strands have strong potential as a biodegradable alternative to nylon. The 1:1 blend of 3% sodium alginate and 3% lignin had the highest breaking force among the biopolymer samples, and was significantly stronger than even the twisted nylon in tensile strength. Although the t-test between these two groups gave a p-value of 0.380674, meaning the difference wasn’t statistically significant, this doesn’t mean the materials aren’t comparable. Instead, it reflects that there wasn’t enough consistent data to confirm a difference, especially given the small sample size and variability between trials.

Although lignin somewhat helped with strength, it also came with tradeoffs. As lignin concentration increased, the strands became stiffer, more brittle, and harder to extrude consistently. The 1:1 ratio was the strongest, but the most difficult to work with, while the 90:10 sample was much smoother and more flexible but didn’t show improvement in strength over alginate alone. This pattern suggests that while lignin improves tensile properties to some extent, the ratio needs to be balanced carefully and mixed thoroughly to avoid making the stands unusable/uneven.

Elasticity emerged as a major limitation of the alginate-lignin composites, as well as the nylon. Both the nylon and alginate strands show minimal elastic recovery and often couldn’t stretch at all due to their brittleness.

Another critical observation involved the extrusion process itself. Manual extrusion introduced irregularities in strand thickness and sometimes trapped air bubbles within the material, forming weak points. These defects contributed to the standard deviation observed in the tensile strength data and the wider range in the data tables. In contrast, nylon formation produced much more uniform strands when twisted and prepared under controlled conditions.

Linear density further highlighted the physical differences between nylon and the biopolymer samples. While nylon exhibited a low linear density of 0.0014 g/cm, the alginate-lignin strands ranged from 0.0029 to 0.0076 g/cm, indicating that the biopolymers were significantly heavier and thicker [Table 2]. This difference could impact wearability, comfort, and flexibility, especially in applications requiring lightweight or finely woven fabrics. To address this, future research should focus on reducing strand diameter through controlled extrusion, post-processing methods (e.g., mechanical drawing), or dilution with lower-viscosity polymers.

Despite these challenges, the materials used in this study offered clear sustainability advantages. Sodium alginate is a biodegradable, widely available polymer already used in the food and medical industries. Lignin, as a low-cost byproduct of the paper and bioethanol industries, is similarly sustainable. Together, they form a cost-effective and environmentally responsible foundation for textile innovation, provided that processing techniques are improved.

In conclusion, sodium alginate-lignin strands, especially a 1:1 ratio, showed measurable potential to replicate the strength characteristics of nylon. Although their elasticity and consistency require significant refinement, this research served as a strong starting point for creating biodegradable, sustainable textile fibers. With continued innovation in formulation and processing, alginate-lignin composites could support the shift toward more environmentally conscious materials in the fashion and textile industry. As a next step, pilot-scale production trials should be pursued to evaluate the material’s performance under realistic manufacturing conditions. Additionally, collaboration with biopolymer scientists and textile engineers could help refine fiber composition, enhance elasticity, and improve strand uniformity, accelerating the development of viable biodegradable alternatives for commercial use.

Bibliograph

Bogers, L. (n.d.). Alginate strings. ALGINATE STRINGS - Loes Bogers.

https://class.textile-academy.org/2020/loes.bogers/files/recipes/alginatestring/

2. Grineviciute, D., Krauledas, S., & Gutauskas, M. V. (2012). Hand evaluation of clothing

fabrics from new biodegradable fibres. International Journal of Clothing Science &

Technology, 24(3), 201–210. https://doi.org/10.1108/09556221211232801

3. Jin, Yanhong, Jiaxian Lin, Yu Cheng, and Chunhong Lu. 2021. "Lignin-Based

High-Performance Fibers by Textile Spinning Techniques" Materials 14, no. 12: 3378.

https://doi.org/10.3390/ma14123378

4. McKay, I., Vargas, J., Yang, L., & Felfel, R. M. (2024). A Review of Natural Fibres and

Biopolymer Composites: Progress, Limitations, and Enhancement Strategies. Materials

(1996-1944), 17(19), 4878. https://doi.org/10.3390/ma17194878

5. Organic Chemistry Laboratory (2017). Experiment 15 – Synthesis of a Polymer:

Nylon-6,6. West Virginia University, Morgantown, West Virginia.

https://community.wvu.edu/~josbour1/Labs/S2017/Exp%2015%20-%20Nylon_2017.pdf

6. Parameswaranpillai, J., Gopi, J. A., Radoor, S., Krishnasamy, S., Deshmukh, K.,

Hameed, N., ... & Sienkiewicz, N. (2023). Turning waste plant fibers into advanced plant

fiber reinforced polymer composites: A comprehensive review. Composites Part C: Open

Access, 10, 100333.

7. Suran M. (2018). A planet too rich in fibre: Microfibre pollution may have major

consequences on the environment and human health. EMBO reports, 19(9), e46701.

https://doi.org/10.15252/embr.201846701

8. The Tech Interactive (2023). Biotinkering Program for Science Center: Algae String

[PDF]. The Tech Interactive, San Jose, California.

https://www.thetech.org/media/bj0brqj5/algae-string-final-draft-2-compressed.pdf

9. Xu, J., Jiang, Z., Hou, F., Zhu, K., Xu, C., Wang, C., & Wang, H. (2022). Preparation and

Mechanism of Bio-Based Sodium Alginate Fibers with Flame Retardant and

Antibacterial Properties. Polymers, 15(1), 154. https://doi.org/10.3390/polym15010154

10. Xu, J., Jiang, Z., Hou, F., Zhu, K., Xu, C., Wang, C., & Wang, H. (2022). Preparation and

Mechanism of Bio-Based Sodium Alginate Fibers with Flame Retardant and

Antibacterial Properties. Polymers, 15(1), 154. https://doi.org/10.3390/polym15010154